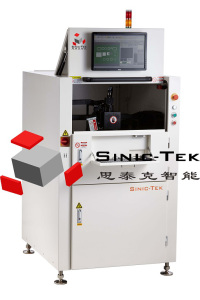

High Performance 3D SPI Online Solder Paste Inspection Machine

Features:

1.The use of PSLM combined with the PMP to achieve 100% high-precision solder paste 3D measurement in SMT production line.

2.Using PSLM technology, changed the traditional way of generating 3D Struct Light, the traditional glass grating moire required mechanically driven by a piezoelectric motor(PZT).By using PSLM, no need glass grating and mechanical parts any more. The elimination of the mechanical drive and moving parts, greatly improving the ease of use and avoid mechanical wear and reduce maintenance costs.

3.By using the Stop&Catch methods combined with multiple image acquisition, realize highly repeatable 3D results on the solder paste measurement. Compared to conventional scanning just take one pictures only on the solder paste a scan sampling, multiple image acquisition greatly enhancing the accuracy and reliable test results.

4.Patened D-Lighting technology achieves full light spectrum detect ability. It is perfect solution to solve the shadow effect and reduce noise interference during 3D measurement.

5.Gerber data conversion and import, achieve automatic detection of the entire board. Manual "teach" function realize user-friendly programming and test job generation in case of no Gerber data situation.

6. The maximum detectable height increased from the traditional±350um to±1200um, not only can detect solder paste, also applies to the detection of opaque objects, such as red glue and black epoxy and other none transported object.

7.Friendly and simple user interface, five minutes of programming and one key operation.

8.Powerful "statistical process control(SPC)", Provide a plenty of tools, user-friendly real-time monitoring, reduce defects caused by poor solder paste printing and improve final product quality.

9.The application range like: mobile phones, tablet PC, computer and accessories, digital cameras, camcorders, automotive, medical, server, LED, FPC, communication products etc.

| Products Description | High Performance Model | |

| Model | InSPIre series | |

| Measurement Principle |

3D white light PSLM PMP(Programmable Spatial Light Modulation,commonly known as moire fringe technology) |

|

| Measurements | Volume,acreage,height, XYoffset, shape | |

| Detection of Non - Performing Types |

Missing print,insufficient tin, excessive tin, bridging, offset, mal-shapes, surface contamination |

|

| Camera Pixel | 5M, 8M/12M as option | |

| Lens Types | Telephoto lens, telecentric lens as option | |

| Lens Resolution | 15um(10/18/20um as option) | |

| FOV Size |

38.4*30.6mm (25.6*24.5/46.1*36.7/51.2*40.8mm) |

|

| Accuracy | XY Resolution):1um;Height:0.37um | |

| Repeatability | Height:<1um (4 Sigma);volume/acreage:<1%(4 Sigma) | |

| Gage R&R | <10% | |

| FOV Speed | 0.3s/FOV | |

| Quantity of Inspection Head | Twin-Heads (Tri-Heads as option) | |

|

Red Green Blue/RGB Three Colas Option Light Source |

Standard configuration | |

| Mark-point Detection Time | 0.5 sec/piece | |

|

Compensation Plate Bending of Real-time Lift in Z-axis |

Standard configuration | |

| Maximun Meauring Height | ±550um ( ±1200um as option) | |

|

Maximun Measuring Height of PCB Warp |

±5mm | |

| Minimum Pad Spacing | 100um ( pad height of 150um as the reference) | |

| Smallest Measuring Size | Rectangle:150um;Round:200um | |

| Maximum Loading PCB Size |

S:X330*Y250mm L:X510*Y505mm LL:X630*Y550mm |

|

| Thickness of the PCB | 0.4-7mm | |

| Height Limitations of the Parts | Top30mm,Bottorm40mm | |

| Board Edge Distance | 3mm , (multifunctional clip edge as option) | |

| Flixble or Fixed Orbit Setting | Front orbit (back orbit as option) | |

| PCB Transfer Direction | Left to right or right to left | |

| Orbit Width Adjustment | Manual, automatic as option | |

| SPC Statistics |

Histogram;Xbar-R Chart;Xbar-S Chart;CP&CPK;%Gage Repartability Data;SPI Daily/Weekly/Monthly Reports |

|

| Gerber & CAD Data Imput |

Support Gerber format(274x,274d);Manual Teach model ; CAD X/Y,Part No.,Package Type imput |

|

| Industry 4.0 Configuration | 1D/2D camera Barcode, Badmark function, print closed-loop control | |

| Computer type | DELL Precision Workstation | |

| Computer Configuration | CPU | Intel 6-core (Intel double CPU 12-core as option) |

| RAM | 16G(24/32/48G as option) | |

| GPU | 2G discrete graphics (4G DP as option) | |

| Hard disk | 1T (2T as option) | |

| DVD+RW | Standard configuration | |

| Operating System | Windows 7 Professional ( 64 bit) | |

|

Equipment Diemension and Weight |

S/L:W1000xD1000xH1525mm;865KG LL:W1200xD1500xH1530mm;1080KG |

|

| Power | 220V,10A | |

| Air Pressure | 4~6Bar | |

| Power (Start / nornmal) | Start:2.5kw / Normal operation:2kw | |

|

Loading Requirements of the Floor |

600kg/m² | |

| Options |

Multifunctional clip edge, 1D / 2D Barcode scanner, Badmark function, print closed-loop control, out-line programming software, maintenance was optionkstations, dynamic Mark point read function, coaxial Mark point camera , UPS continuous power supply |

|